The Solid Liquid Integrated Cycle (SLICE) rocket engine uses a solid propellant gas generator for the fuel and a liquid oxidizer. The propellants are combusted in an array of small thrusters with the exhaust expanded on an aerospike nozzle. SLICE reduces cost by using safe, easy to handle propellants and by taking advantage of economy of scale in the manufacturing of the thrusters. The objective of this effort was to mature SLICE propulsion technology in order to prepare it for use on NASA Armstrong Flight Research Center’s Towed Glider Air Launched System (TGALS).

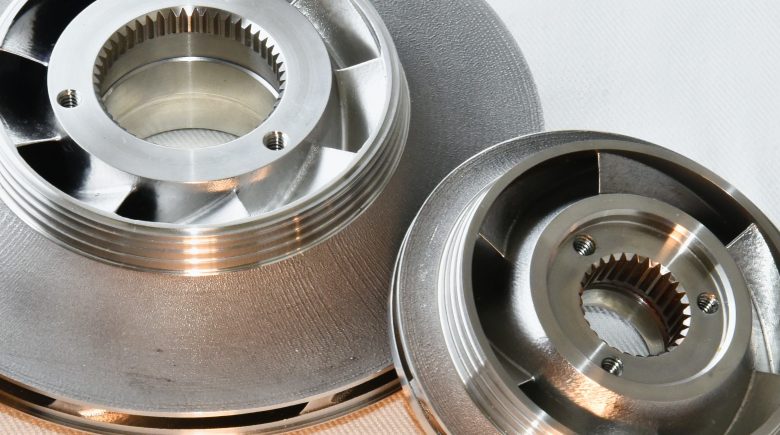

The Low-Cost Turbopump for Expendable Launch Technology (LCTPA) program engineered and fabricated a low-cost turbopump for to meet the cost objectives of the DARPA XS-1 vehicle engine. The turbopump is a “clean sheet” design for a 35k pound force engine and utilizes additive and traditional manufacturing technologies to reduce part count and machining time. The system is a single shaft liquid oxygen pump and liquid hydrogen pump driven by an expander cycle powered methane turbine.

The Low-Cost Turbopump for Expendable Launch Technology (LCTPA) program engineered and fabricated a low-cost turbopump for to meet the cost objectives of the DARPA XS-1 vehicle engine. The turbopump is a “clean sheet” design for a 35k pound force engine and utilizes additive and traditional manufacturing technologies to reduce part count and machining time. The system is a single shaft liquid oxygen pump and liquid hydrogen pump driven by an expander cycle powered methane turbine.

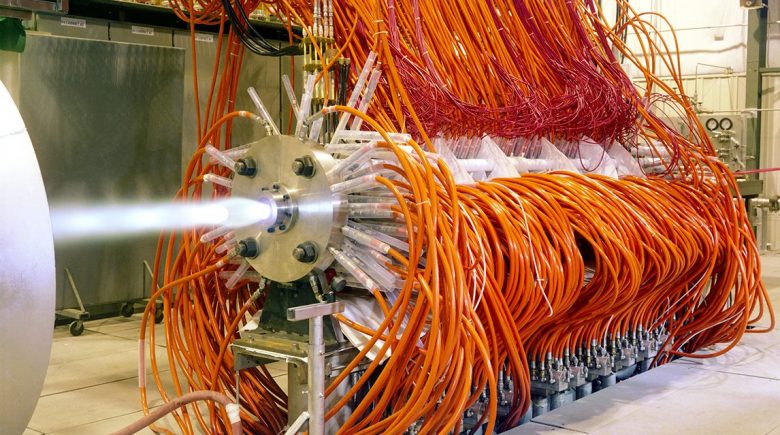

The Hybrid Upper Stage Booster (HUSB) Phase II program achieved all of its objectives. The feasibility of the Solid/Liquid Integrated Cycle Engine (SLICE) propulsion concept has been decisively demonstrated. A gas-generator propellant designated as Exquadrazine 6514 was developed that is low cost, but has high performance. The propellant received a Department of Transportation (DOT) hazard classification of 1.4C, which is the safest possible rating for a formulation that is designated for use in rocket propulsion. The engine ignited readily and smoothly in all tests. Combustion was stable with smooth transients during throttling. The effort concluded with a test of three combustors operating from a single gas-generator with the exhaust exiting on a section of an aerospike nozzle.

The Hybrid Upper Stage Booster (HUSB) Phase II program achieved all of its objectives. The feasibility of the Solid/Liquid Integrated Cycle Engine (SLICE) propulsion concept has been decisively demonstrated. A gas-generator propellant designated as Exquadrazine 6514 was developed that is low cost, but has high performance. The propellant received a Department of Transportation (DOT) hazard classification of 1.4C, which is the safest possible rating for a formulation that is designated for use in rocket propulsion. The engine ignited readily and smoothly in all tests. Combustion was stable with smooth transients during throttling. The effort concluded with a test of three combustors operating from a single gas-generator with the exhaust exiting on a section of an aerospike nozzle.

Exquadrum developed an innovative, yet highly cost effective, approach to the fabrication of new arcjet heater segments for this research project. Segmented arcjet heaters support the critical development of hypersonic capabilities for the US DoD. Arcjet facilities reproduce thermal environments encountered during flight from Mach 8 to 20. Work completed on the program resulted in the award of US Patent 7,509,851 B1

Exquadrum developed an innovative, yet highly cost effective, approach to the fabrication of new arcjet heater segments for this research project. Segmented arcjet heaters support the critical development of hypersonic capabilities for the US DoD. Arcjet facilities reproduce thermal environments encountered during flight from Mach 8 to 20. Work completed on the program resulted in the award of US Patent 7,509,851 B1